combiloop CL6G

COMBILOOP CL6 G: THE COMPACT CL SYSTEM REVOLUTION

As the world's first compact, self-contained high-pressure cooling lubricant system for large machining tools, combiloop CL6 G takes your machining efficiency to the next level - in the best form, function and perfectly integrated. The innovative, modular configuration – from the disinfection to the cooler – not only brings better machining results, but also boosts profitability, sustainability and saves space.

Suitable for lathes by:

Citizen, DMG Mori, Manurhin, Star, Tornos, Tsugami, to name but a few.

DISCOVER THE COMPACT CL SYSTEM REVOLUTION IN OUR VIRTUAL SHOWROOM

| Technical Data | CL6 G 800 | CL6 G 1200 | CL6 G 2500 | |

|---|---|---|---|---|

| Equipment |

|

|

| |

| Connection |

| |||

| Pumps |

|

|

| |

| Delivery rate |

| Maximum 300 l/min | Maximum 450 l/min | |

| Filter/Filtration fineness |

|

|

| |

| Operation |

| |||

| Options (selection) |

|

|

| |

| Degree of machine contamination more |  | |||

FUNCTION

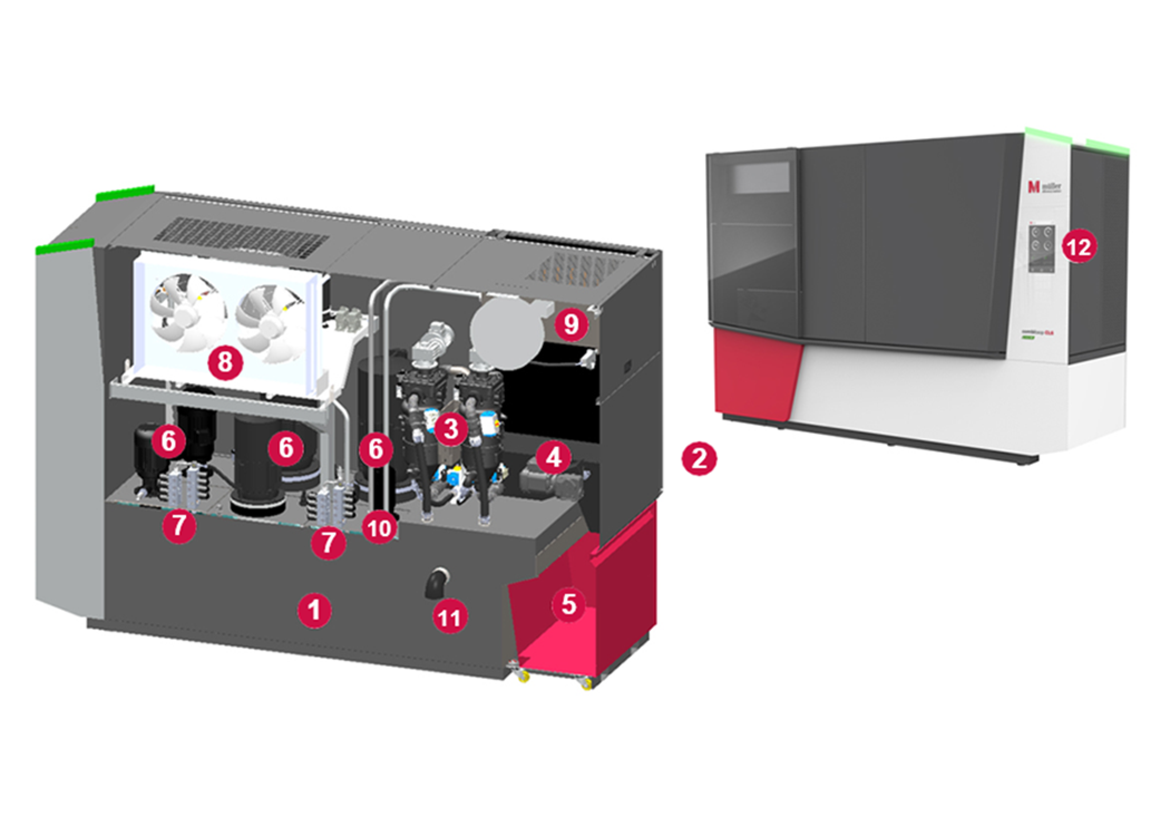

Caption:

- Clean liquid tank

- Centrifugal pump for filter circuit (on machine tool)

- Self-cleaning automatic filter (optional)

- Automatic discharge for filter sludge

- Integrated chip carrier with tipping function

- eco+ high-pressure pump incorporating control pump technology / low-pressure pumps (depending on pump configuration) (cutting oil) // eco+ speed-controlled high-pressure pump / low-pressure pumps (depending on pump configuration) (water emulsion)

- Valve block with controllable service connections

- Cooling system / plate heat exchanger (optional)

- Disinfection system (optional)

- Skimmer (optional)

- Overflow for bypass filtration

- Electrical controller with touch panel for system operation

DOWNLOADS

Interested?

Please give us a call or send us an email. We are looking forward to helping you.

phone: +49 (0)741 - 174 575 - 0

info[at]muellerhydraulik.de